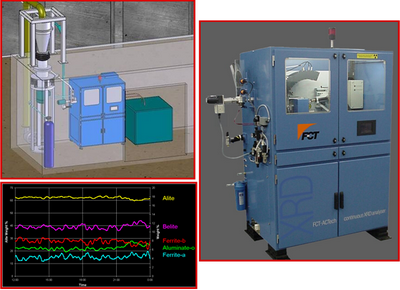

On line Clinker XRD analyser COSMA

THIS ANALYSER MEASURES THE MINERAL COMPOSITION OF CLINKER ON LINE

Key information for the cement manufacturing process to guarantee the end product quality with optimized burning conditions and alternative fuels use

Advantages :

- Automatic on-line equipment requiring no human intervention

- Up to 3 sampling points can be controlled by the same analyser

- Monitoring and control of kiln operations

- High cost savings by adjustment of burning conditions & alternative fuels use

- Continuous measurement of clinker quality using Rietveld

- Full pattern collection with fixed 120 degree area detector, providing real time analysis

Principles :

- Custom designed automatic sampling & transport systems

- Clinker grinding

- Continuous ground clinker feeding towards the analyser’s turntable

- Continuous XRD analysis with fixed detector

- Output data transmitted to the kiln management unit

- Sampled clinker automatically returned to the process

Performances :

- Continuous analysis : from 50 to 100 g/min are analysed

- High performance grinding unit that guarantees a constant fineness

- No sample cross contamination

- Static repeatability :

| Mineral Phase |

Range (%) |

St. Dev. (%) |

| Alite (C3S) |

40 - 7 |

0,8 |

| Belite (C2S) |

5 - 20 |

0,8 |

| Aluminate (C3A) |

5 - 15 |

0,4 |

| Ferrite (C4AF) |

5 - 20 |

0,4 |

| Free Lime (CaO) |

0 - 1,5 |

0,07 |

| Gypsum |

0 - 6 |

0,3 |

| Bassanite |

0 - 6 |

0,3 |

| Calcite |

0 - 15 |

0,3 |

Specifications :

- Height : 2000 mm

- Depth : 800 mm

- Length : 1800 mm

- Weight : 600 kg

- Power supply : any from 380 to 600 V; 50-60 Hz

- Compressed air supply : 6 bars, dry and clean

- Location : close to the cooler(s)

|