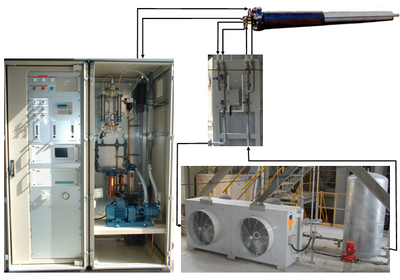

Gas sampling & analysing system AGO2

ON LINE ANALYSIS : THIS SYSTEM ALLOWS THE OPTIMIZATION OF THE KILN OPERATION

Precise control of the CO, O2, CO2, CH4, and NOx contents in the fume box chamber

Advantages :

- Automatic on-line equipment working on a continuous basis

- Output information used to control and optimize the burning operations, typically :

- Energy savings when controlling the O2

- Fast response to reduction conditions in the kiln so as to avoid the formation of CO

- Optimizing the burning zone temperature when controlling the NOx

- Water spray based system (no need of any ceramic filter) ensuring a higher reliability

- Programmable self cleaning of the sampling tube with high pressure (8 bars) water pulses which prevent any sample contamination from air purge

- High torque sampling probe extraction system

- Integrated industrial water filtration

- Adaptable to any brand of gas analyser units

Principles :

- Kiln inlet gas sampling

- Solid and liquid parts of the sample are separated (glass balls filter, sedimentation tank) from the gas itself

- Cleaning operations (cyclone separator, dryer, glass paper filter) of the gas

- Transfer to the analyzers with a constant flow

- Analysis results output to the plant

Performances :

- Sturdy sampling probe (jacket ø = 168 mm)

- Working temperature of the sampling probe : 1 400 °C

- Operating dust concentration : up to 2 Kg/m3

- Liquid ring pump (sampling flow rate of 1800 l/h) requires no maintenance and allows a very short response time (only a few seconds)

- High capacity (2500 l/h) closed circuit probe cooling system (water T° < 65°C)

- Simultaneous measurement of 4 gas

- 2 operating modes: Automatic - Calibration

Specifications :

- Height : 1800 mm

- Depth : 910 mm

- Length : 2000 mm

- Weight : 500 kg

- Power supply : any from 380 to 600 V; 50-60 Hz

- Location : close to the fume box chamber

|